The Wonders of Bio-crete

By Nic Lim

Introduction to the Wonders of bio-crete and why its’ use may mitigate environmental destruction and create more comfortable low-carbon buildings.

What is Bio-crete?

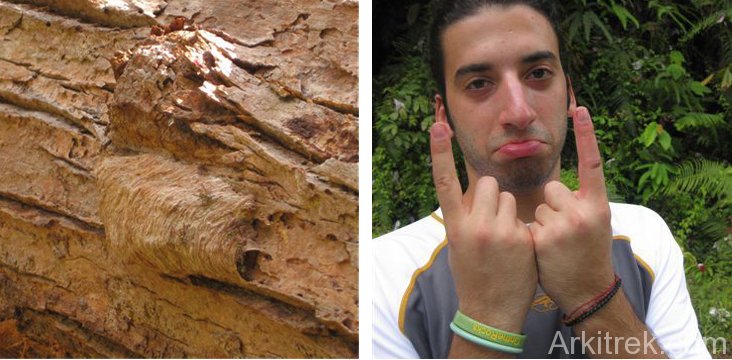

Bio-crete is a concrete-like material based on a mixture of natural fibre and hydrated lime or calcium hydroxide (hereinafter referred to as lime). In Europe hemp fibre is often used. In Malaysia, where hemp is hard to come by, we’ve looked to coconut coir, oil palm kernel fibre or rice husk. Often these fibres are found as agricultural waste.

How Does it Work?

In a typical concrete mix, cement binds together mineral aggregates of varying sizes to produce a dense material with high compressive strength. In bio-crete, natural fiber replaces most of the aggregate and lime is used as the binder. Sand can also be added to bio-crete to increase density, thereby increasing its load bearing capacity but at the cost of its thermal insulating properties. The lime binder hardens by reacting with carbon dioxide to form calcium carbonate. Some sources suggest that in natural fibres with a high silica content (rice husk, hemp shiv) a petrification process occurs which extends the lifespan and increases the compressive strength of bio-crete. We’d like to know more about what happens to fibres in bio-crete over time if anyone can help?

Why Lime?

Where cement is the conventional binder since the turn of the 20th century, Lime was the traditional binder for centuries before that. Lime has the following properties that makes it a preferred binder for our cause:

1. Time has proven it to be long-lasting. The colonial era architecture of the Straits Settlements of Penang, Melaka and Singapore all use lime mortar and renders.

2. It is hygroscopic or moisture permeable. This allows the material to help regulate temperature and humidity within a building. In a hot and humid climate like Malaysia, we believe that lime-based materials can help cool a building through evaporation when the air temperature increases and relative humidity drops. A sweating building?

3. Lime is weaker than cement. In this case a strength because where concrete requires expansion joints, lime-based construction can expand and contract with less risk of cracking.

4. Natural fibre in bio-crete creates a lightweight insulating material which can help keep the sun’s heat out and the air-conditioner’s coolth in.

5. A lime binder takes longer to cure so there is less wastage during construction. How many bags of cement have you had to throw away because they’ve gone hard? Of course this can also be a disadvantage on a fast-track building project.

Low Carbon & Environment Friendly?

Bio-crete is believed to be a carbon neutral or even carbon negative material. Reasons for this are as follows:

– Making lime can be less energy intensive than making cement.

– Lime absorbs carbon dioxide when it hardens (as does cement).

– Plants sequester carbon dioxide in their natural fibres as they grow.

– Replacing stone and sand aggregates with locally sourced lightweight natural fibres reduces the embodied energy of quarrying and transportation.

Note that using lime is destructive to nature because it’s production necessitates quarrying of limestone. We think that lime-based bio-cretes, such as coco-crete may only go some way to mitigating environmental damage, rather than avoiding it altogether.

The jury also seems to be out on whether bio-crete is carbon neutral or carbon negative. This Inhabitat article about Tradical Hemcrete suggests that it is carbon negative, whereas the Tradical website only claims to ‘significantly reduce carbon emissions’. The Inhabitat article doesn’t seem to be well researched though, if you read the comments. Is there any good research on this subject? We’d like to know.

Applications of Bio-crete

Technically you could have a building built entirely out of lime-based concrete. The best example would be the Roman Pantheon which used lime and volcanic ash, mixed with stone aggregates of varying densities.

Bio-crete is generally not intended as a load-bearing material and the mixes that Arkitrek has experimented with are more suitable for infill walls, rather than structural elements.

One of the main weaknesses of the bio-crete is that it takes up to five times longer than concrete to cure. Although this may be a drawback when chasing down a construction date line, it would also mean that the lime used in bio-crete doesn’t expire as quickly as cement, thus reducing wastage.

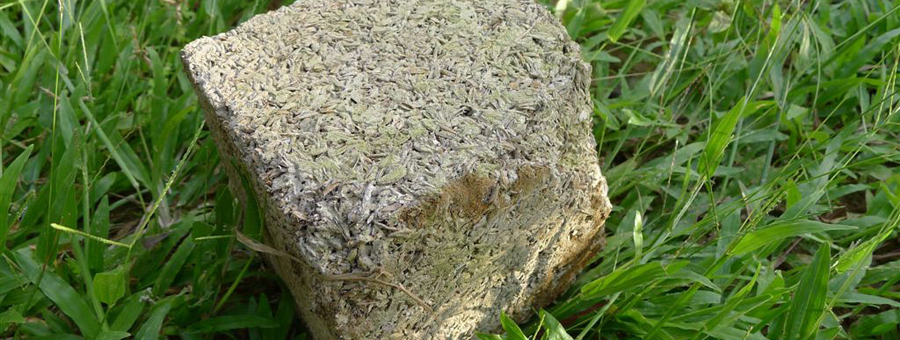

To overcome this, Arkitrek is looking forward to experimenting with bio-crete bricks instead of cast in-situ. This means that we would be able to inject all the benefits of the bio-crete into a single brick, and at the same time eliminating the long curing time required by in-situ casting, guesswork needed when ordering different materials for a project, and wastage from improper storage of materials or usage. This would also mean that each and every brick could be quality controlled to ensure uniformity in the material’s composition, thereby maximizing the material’s potential.

What’s Next for Bio-crete?

There is still a lot of potential to experiment with bio-crete. Turning it into a brick-form is just one way of going about it in terms of usage, but there are also methodologies to refine, recipes to be tested and re-tested, as well as a range of materials that we could hopefully dump into the mix to give us the effects that we require.

For example, we know that rice husk ashes (RHA) are pozzolanic; they react with lime and water to act as a cementitious binder. Adding RHA to biocrete could alter the performance of bio-crete, but we’re getting into some heavy chemistry here. If any chemistry or engineering boffins want to use Arkitrek projects for field testing super bio-cretes we’d like to hear from you!

From the range of materials to mix with, the design usage and application, there is still much potential for bio-crete that is un-explored. Arkitrek aims to conserve natural resources through design. Popularising bio-crete will allow us to reduce or phase out the energy intensive, environmentally harmful and non-renewable quarrying for cement and mineral aggregates in favour of more responsible alternatives. The fact remains that lime production still destroys nature and that’s something we need to get our head around. Meanwhile, we believe that the performance benefits to buildings and the value added to agricultural waste and rural communities make bio-crete worth pursuing.