In the Shit – A Septic Tank Guide

This post has been updated. The original ‘in the shit, a septic tank guide’ has been archived .

Two common misconceptions about septic tanks.

1. Septic tanks are an acceptable sewage treatment solution

2. Septic tanks are not supposed to overflow

The first misconception is the biggy; A septic tank on its own is not good enough to treat sewage waste to an acceptable standard. Further treatment is required. The second misconception shows a basic misunderstanding of the processes at work in a septic tank.

This article illustrates what happens inside a septic tank, what should happen after the septic tank and appropriate effluent standards to be aiming for. To build your own brick septic tank you can download our design for free

Septic Tank Processes

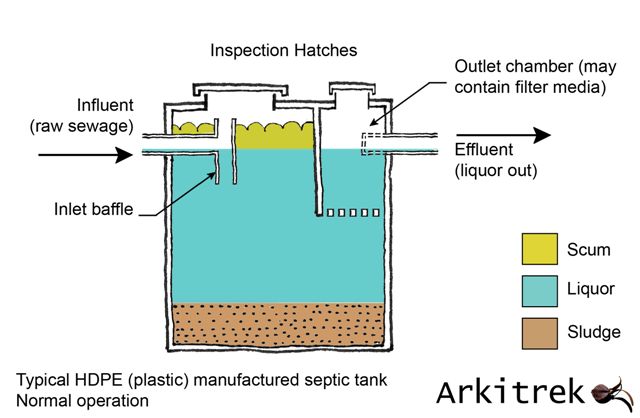

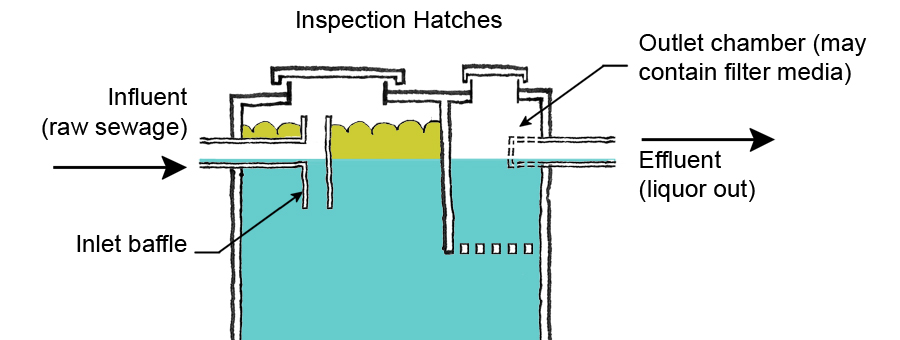

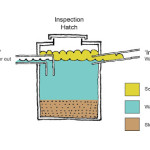

The following illustration shows a cross section through a typical off-the-shelf plastic septic tank under normal operating conditions.

Septic tanks operate by displacement and do not normally require pumps. Each time a new ‘delivery’ arrives at the influent (inflow) pipe it will displace an equal volume of liquor at the effluent pipe. Septic tanks should be filled up with water when they are commissioned and thereafter will continuously ‘overflow’ as long as there is raw sewage going into them. When I say ‘overflow’ I mean liquor will flow out of the discharge pipe, not that liquor will overflow from the inspection hatches. We’ll come back to this in a bit in the ‘de-sludging’ section.

Septic tanks should be designed with a retention time of at least 24 hours. i.e. it takes 24 hours for liquor to pass through the tank. The size of the septic tank should therefore be equal to or greater than the total volume of sewage waste produced in 24 hours.

This 24hour retention time is enough time for the sewage waste to separate into three constituent parts: sludge, liquor and scum. 24 hours is not long enough to treat the sewage waste to an acceptable standard. We’ll come back to what is an acceptable standard in a minute.

The Sludge

Most solids will settle to the bottom of a septic tank where they will slowly accumulate forming a liquid sludge. A baffle on the inlet pipe will slow down new deliveries so that they don’t disturb the settling process and also limit short-cutting.

The Scum

Mostly fats, oils and grease (FOG) which are less dense than water so they float. Scum can form a fairly hard crust which will slowly be digested by bacteria in the septic tank. Baffles on the inlet and outlet pipes help to prevent them being blocked by scum.

The Liquor

This is not clear water but nor is it raw sewage so it is called liquor for want of a better word. The level of the entrance to the outlet pipe or chamber should be within the liquor layer so that neither sludge nor scum leave the septic tank.

De-Sludging

Sludge will get deeper and eventually need to be removed. This is usually done by a ‘honey dipper’ as the Americans euphemistically call it. In reality it’s a tanker truck with a big dirty vacuum cleaner. Sludge pumped out into a tanker can be removed to a municipal sewage treatment works. In Malaysia there is no guarantee that this is an effective solution and we believe that architects and engineers have a duty to verify the performance of the local municipal treatment plant before choosing this option as the most responsible way to discharge sewage waste.

On sites without road access the sludge can be pumped out using a mobile pump. The sludge should be stored in an adjacent tank for 6 months to digest, after which lime can be added to raise the pH which kills any remaining pathogens. This process is called stabilisation. After stabilisation sludge can be dried on a drying bed and used for fertilizer. Stabilised sludge can also be used directly as liquid fertilizer.

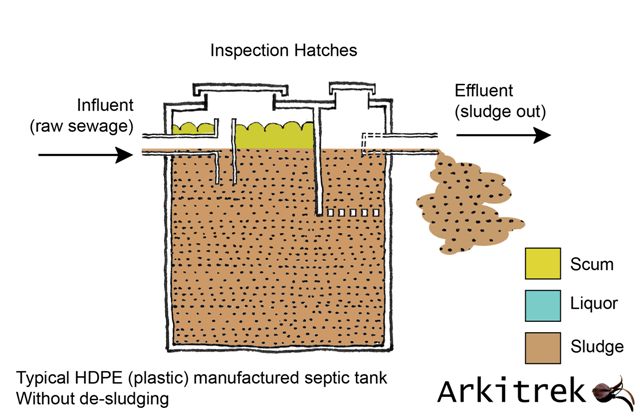

The above illustration shows what happens if sludge is not cleaned out, but instead allowed to reach the outflow level of the effluent pipe. Any new delivery will cause sludge to be displaced as effluent. Clearly this is not good. In some cases the effluent pipe will become blocked and scum followed by sludge will come out through the inspection hatch or back up into the building. Clearly this is not good either. It is usually fairly obvious when this starts to happen because of the smell.

Perhaps more importantly, if sludge is allowed to flow out of the septic tank it may compromise the efficiency of the overall sewage treatment process. As we have seen at the beginning; a septic tank on its own does not treat waste to an acceptable standard. So what will?

After the Septic Tank

Here are the three sewage treatment options which we have tried in combination with a septic tank.

Aeration

By far the best option for sewage treatment is aeration. In a septic tank, digestion of the sewage waste takes place an-aerobically (without oxygen). Anaerobic digestion takes a long time, certainly much longer than the 24 hours retention time of a septic tank. If we were to rely on anaerobic digestion we would need very large tanks to provide the necessary retention time.

As soon as you introduce air into the sewage treatment process things speed up dramatically. This is because bacteria + oxygen are much more efficient at digesting sewage waste than bacteria without oxygen. With aeration, sewage waste can be acceptably treated with retention times of less than 24 hours. Tank size and overall plant space can be kept small.

An aeration system would typically use a septic tank to separate out sludge, liquor and scum as we have seen. The liquor will then be pumped or displaced through a series of two or more aeration tanks. The big advantage of this system is space saving and high quality of the finished effluent. The downside is that it is more expensive to set up and requires more maintenance than some low tech solutions.

Leach Field

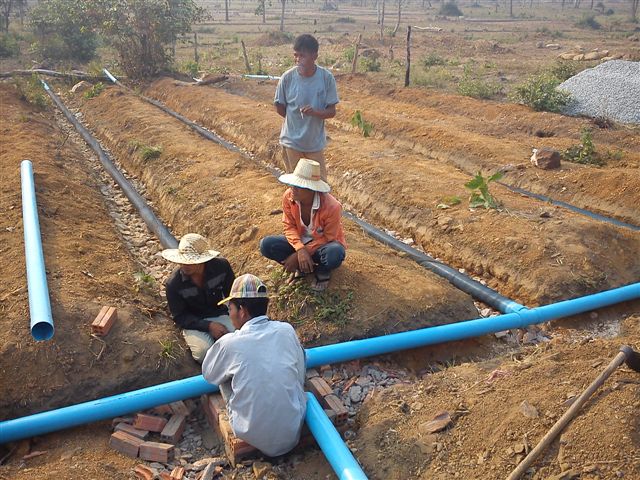

A leach field is the preferred partner for septic tanks worldwide. The principle is to take the liquor from a septic tank and distribute it to a network of perforated pipes buried under the ground. The liquor will seep into the soil where bacteria will digest the organic waste and roots of plants will take up water, nutrients and minerals.

This system relies on the soil being porous but not too porous and also that the ground is not waterlogged. In Malaysia we have found that leach fields do not generally work due to the high rainfall and propensity for waterlogged ground. The converse is true of sandy areas like coral islands where effluent from a leach field would drain through the soil too quickly and enter water courses, aquifers or the sea before it has been adequately treated.

The advantage of a leach field is that it is low tech and cheap. The septic tank must be de-sludged regularly so that sludge does not overflow and block up the leach field but apart from that they are relatively maintenance free. The disadvantage is that they use up a lot of space and require suitable ground conditions.

The following photo shows a leach field being installed by Camps International in Cambodia.

Constructed Wetland

A constructed wetland is a series of ponds of varying depths with either an open or closed water surface. The latter is achieved by infilling the ponds with large grade gravel. Constructed wetlands rely on a mixture of aerobic and anaerobic digestion and the uptake of nutrients and minerals by plant growth.

The advantage of a constructed wetland is that plant species can be carefully selected to remove specific metal and mineral contaminants. They are also low tech and relatively maintenance free. The disadvantage is that they require a large area and are expensive to build, although not as expensive as an aeration system.

A drawback that we have found with constructed wetlands is that typical septic tank liquor is still far too nasty to discharge directly to a wetland. It smells and kills the plants. An intermediate treatment is required; perhaps a single small aeration tank, a large anaerobic digestion tank or an oxidation pond.

Composting Toilets

Composting toilets are an excellent way of treating toilet waste. In a tropical climate they quickly produce a neutral and odourless organic fertilizer. The drawback in Malaysia is mostly cultural; Malaysians like to use a lot of water in their toilet and water is the enemy of a composting toilet. With every deposit in a composting toilet there must be a corresponding addition of dry organic material such as saw dust or rice husk to soak up the excess liquid.

The other drawback of a composting toilet is that although they deal with piss and jobbies, you still have to treat grey water from your shower, laundry and kitchen waste. This grey water can be every bit as nasty as so called black water and must be treated as such. Soaps plus other fats, oils and grease (FOG) in particular must go through a sewage treatment process to digest them.

You can’t get away from the need to treat liquid sewage waste to an acceptable standard, whether it is black water or grey water.

Acceptable Standards for Sewage Treatment

Keeping it simple (because we’re architects not chemists) there are several things to measure in your sewage effluent but BOD and Suspended Solids (SS) are the two main ones for domestic waste.

Biological Oxygen Demand (BOD) is a measure of the potential for the effluent to remove oxygen from any water that it is discharged into. This is important because removing oxygen from water will kill other things such as fish, invertebrates and plants that might also need to remove oxygen from the water. An obvious visual sign of high BOD are algal blooms; coloured blue or green in fresh water and red in the sea.

Malaysia has two standards for treatment of sewage waste; Standard A is for discharge into drinking water catchment areas and Standard B for all other areas, including the sea. We believe that as a rule of thumb standard A should be the minimum target everywhere.

Standard A criteria are; BOD = 20mg/l @ 20ºC and SS = 50mg/l

A typical septic tank effluent is BOD = 118 to 189 mg/l (this is about a 40% reduction from the level of the entering sewage) and SS = 38 to 85 mg/l. source: Tomher Environmental A septic tank is therefore not likely to meet Standard A for BOD but might scrape through Standard A for SS.

Sewage also contains pathogens such as bacteria like E. coli or parasites and viruses. A septic tank achieves little or no reduction in the level of pathogens. Even treated sewage to Standard A or above will still contain pathogens. In sensitive areas such as bathing beaches and areas of fish production for human consumption, disinfection of the effluent after treatment may be necessary.

Conclusion

Septic tanks work well as a primary settlement tank at the start of a sewage treatment system. They do not treat sewage waste to what we deem to be an acceptable standard. To do this a septic tank must be combined with appropriate secondary treatment. Simply discharging septic tank effluent directly into a stream or sand near the beach is not good enough, although I have to confess, on some of our projects we are still doing this. There’s always room for improvement and the key message here is not to ignore the problem in the hope that it will go away!

To build your own brick septic tank you can download our design for free here

No shit!

Good works…now we can use this as our reference.

George

I have done quite a bit of research into this over the years as well, not something I announce at many dinner parties but it is a subject of some importance since I, like you, have had to construct accommodation in remote places.

I do know that DBKK have a pump for these tanks and they charge a small fortune to do the business for you, from what they tell me the sludge is put into the sewerage system. So that is in KK and surrounding area, a remote location is a different kettle of poo.

The ‘water’ that comes out from the tank is full of nutrients and causes localised eutrophication, this can be quite bad if the discharge is straight into a river. At Agathis camp you can see where the discharge is as there is a small area where the plants are overgrowing at a very fast rate!

There are equations to help you to work out how long your system will be able to serve your installation or to guide you on what size system you need for the amount of people who will be using it. Many of the ones I have seen require a pump out every five to seven years and like you say, the fliuds can be pumped out and then an organic ‘soaker upper’ put in to solidify and enable the sludge to be dug out – using fire ash mixed in helps a lot to deoderise the stuff.

You have to use a concrete or brick one if you plan to dig out since the plastic ones do not have a removeable lid, we built one in Tabin Wildlife reserve at the centre there using bricks and it works very well…so far.

From the research I have done, composting toilets do not work very well in the tropics and if not managed properly can get colonised with all sorts of creatures, I would love to hear about any system that improves on the septic tank, perhaps one that produces and stores methane for energy generation…..

Thanks, Simon. That’s a useful tip about the plastic ones not being easy to dig out. Obvious really when you look at the size of the lid.

I’ve since done a little more research into the septic tanks at Borneo Rainforest Lodge. The Septic tank for the staff quarters used to have a leach field but it got waterlogged so they have now piped the effluent straight into a watercourse. They have also dug out the sludge by hand and I presume removed it from the site!

All of the tanks at BRL are three-compartment concrete ones. I have checked three of them and the effluent is clear and I can put my nose quite close to it with no ill effect.

This is in contrast to the Agathis camp one which as you say has caused some abundant growth at the discharge point and is also quite smelly. A similar problem appears to afflict the Resthouse at DVFC. It would be interesting to know how the design of these systems compares to BRL i.e. whether they are three compartment or less and when they were last emptied.

The hydroponic system at Langkayan Island (to which I alluded in my post) is presumably a more controlled way to use up the extra nutrients before discharging effluent into the environment. In the photos I have seen they appear to uses yams growing in plastic vats for this purpose.

I have also been looking into the design of methane (biogas) collectors on septic tanks. These apparently work best when you include dung from pigs or ruminant domestic animals. The best use for the methane seems to be for lighting and cooking (once you have scrubbed out the sulphur dioxide using wire wool the gas is odourless). I am trying to find a suitable site for a biogas demonstration project so if you have any ideas please let me know.

Thanks again for the feedback

Hi,

I am working towards construting a holiday retreat on a white sandy Island and would like to know what would be the better septic system to use on the island?

Thanks/Emson

Dear Emson. As mentioned, sand is very porous so a leach field will not be acceptable.

If you’ve got lots of space then an anaerobic system may be cheaper and more fool-proof – combine closed tanks for primary/secondary treatment and open constructed wetland for tertiary treatment.

You could also research ‘recirculating sand filters’ but we have no experience of these.

If space is at a premium then an aerated system is the way to go.

Can septic tank sludge be used in a biodigester to produce biogas, or, is it already digested?

Pingback: Brick Septic Tank Arkitrek Open Source Design Drawings

Pingback: Biogas Collector

Pingback: Leach Field Open Source Design Drawing