Futur Arc: Environmentally Responsible Sewage Treatments

Down To Earth Matters: Environmentally Responsible Sewage Treatments

The following article appeared in the 2011 1st Quarter edition of Futur Arc magazine

By Sarah Greenlees

We have treated the oceans as a “supermarket and a sewer;” Sylvia Earle, a prominent oceanographer and conservationist, was recently quoted to say in Time magazine [i]. As a result we put at risk the earth’s capacity to balance carbon dioxide and other gases in the atmosphere as well as destroying some of the least explored ecosystems.

A recent study into the world’s rivers led by Charles Vörösmarty of City Collage, New York (published in Nature magazine; 30 Sept 2010; “Rivers in Crisis”) revealed that 80% of the world’s population lives in areas where the rivers are in a threatened state [ii].

Architects striving to have a low impact on the land should also consider the impact of development on our seas and waterways. This makes treatment of sewage one of the most important factors of environmentally responsible design. In rapidly developing countries municipal sewage treatment plants are often oversubscribed and have trouble keeping up with the rate of development. Feeding into the municipal line in this case merely side steps the issue of responsible sewage management rather than finding a solution.

Architects Hasegawa & Xavier, of Malaysia are trying to reduce dependency on poor quality municipal infrastructure. One option is to treat sewage on site; however conventional systems such as extended aeration take around 24 hrs to digest waste, have a large footprint, require a fairly high level of maintenance and are prone to break downs resulting in unpleasant odour problems. Recently, a new product has been introduced in the South East Asia region by Tomher Environmental Sdn Bhd – the Enhanced Extended Aeration Processing System, or BioSolve.

The Infinity BioSolve system concentrates on providing optimum conditions for microbial life, the system is more efficient and is able to digest sewage in a quarter of the time of conventional systems. This means that it is a lot smaller. It is also flexible so that it can be designed specific to each site and brief and is far simpler than standard systems to run. Most importantly, it digests sewage to a higher level than current systems and removes virtually all pathogens.

There are two principal by-products of sewage treatment; water and de-watered sludge. In the Infinity BioSolve system, the water effluent typically has a Biochemical Oxygen Demand (BOD) of 5mg/ BOD and 15mg/l SS (suspended solids). This exceeds Australian and European standards, as well as those in South East Asia. BOD is the amount of oxygen required by aerobic micro-organisms to decompose the organic matter in a sample of water, such as that polluted by sewage. It is used as a measure of the degree of water pollution. Liquid sewage effluent can be treated further to remove nitrates and phosphates; however, these chemicals are ideal for irrigation and hydroponics systems.

The sludge from the Infinity BioSolve receives a higher level of digestion and can be turned out to drying beds where the sludge is made into fertilizer. Sludge drying and composting is unlikely to be practical on an urban site therefore it must be discharged to the municipal line. In this case an advantage of Infinity BioSolve is in the reduction in volume and toxicity of waste discharge to be handled by municipal infrastructure.

The flexibility of this system and its effectiveness make it an interesting product. While drying beds are not usually appropriate in an urban centre, hydroponics systems can be adapted to make use of the liquid effluent. Hasegawa & Xavier are currently proposing a vertical garden facade for a new urban project in Kota Kinabalu, Sabah, Malaysia. They also propose that the vertical garden be fed by a modification of the Infinity BioSolve hydroponics system.

The project has approximately 370m² of vertical garden facade. Usually this would be fed with large quantities of water and fertilisers. The proposal to use a hydroponics system linked to sewage treatment will avoid the use of fertiliser and will recycle water from the building, making savings on fresh water consumption. It will also greatly reduce the degree of reliance on municipal infrastructure.

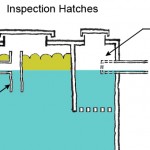

Before the treated sewage is discharged to the municipal line, it is first sent to a balance chamber and drained of fluid. This liquid is pumped to tanks on the roof, from where it will trickle through the containers of plants, below the soil and out of human contact. All the tanks will be aerated and will be adaptations of the Infinity BioSolve reactor tanks. The hydroponics will finish off the cleaning, meaning that the effluent that drains off will be clear water. The rate of flow of fluid through the hydroponics system will be determined by gravity and a series of orifice plates that will control the feed pressure and volume. Theoretically the water run off can be collected and recycled. However, it is possible that after transpiration there will be little run off.

A third by-product of sewage treatment is methane gas. Where the technology exists; this can be collected and used as a fuel. For example, in October 2010, Didcot sewage treatment plant in Oxfordshire, UK, became the first plant in the UK to incorporate bio-methane with fuel gas that was being piped to customers’ homes. This biogas would otherwise be released as a greenhouse gas to the atmosphere.

Despite the reliance on advanced technologies of large scale methane capture, the principle has long been used in small scale biogas digesters where there is no municipal sewage treatment infrastructure available and fuel gas must be delivered in pressurised canisters by road or river. For example in rural Sarawak the cost of a cylinder of gas can be as much as 6 times the normal price in urban areas and this does not count the environmental costs (such as carbon emissions) of diesel fuelled transport [iii].

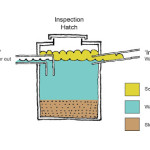

Biogas digesters are a viable low budget, low scale means of dealing with waste and fuel production in rural areas. Malaysian design consultant, Arkitrek have been experimenting with biogas digesters in Sabah. Their design is based on the Deenbandu model that has been successfully used in India for many years. These digesters are usually built by skilled bricklayers. However, Arkitrek wanted to test whether unskilled workers, including volunteer tourists, could build them. The design uses a brick tank with a ferro-cement gas holding dome. Gas is kept under pressure in the dome by water in a displacement tank. Waste is held in the tank for a minimum of 30 days where it is digested anaerobically. The resultant biogas (mostly methane) can be collected and used for cooking and lighting.

Biogas digesters are best fuelled with animal dung mixed with water (pig and poultry dung has the highest energy value per volume). They can also run on sewage and selected kitchen waste providing the quantity of water mixed with the waste is strictly controlled. If there is too much water (such as is used by a typical WC flush cistern) then the biogas digester will not operate properly. Grey water must therefore be treated separately, for example by using a conventional septic tank connected to a leech field or constructed wetland. The effluent sludge from the digester must be dried and composted, after which it can be used as fertiliser. It is thought, that if biogas digesters can supplement septic tanks then two major infrastructure considerations – human waste disposal and energy production – can be dealt with in the same place.

Two prototype digesters are under construction in Malaysia with the help of volunteer organisation, Camps International from the UK. One is at a longhouse near Kudat, Sabah and another is at a wildlife sanctuary in Sepilok, also in Sabah. The design must be robust to tolerate construction by unskilled labour and users must be educated to limit water put into the digester. If the digester is to be fuelled by raw sewage then squat pans or toilets need to be low flush volume or easy flush design and grey water (such as from floor washing) must not drain into squat pans. Both prototypes are currently being tested.

Once the construction and operational challenges have been overcome, the potential for rural areas to have an effective waste treatment and energy production system that is cheap and straightforward to construct is one that Arkitrek feels is worth pursuing. A high standard of environmental water quality is essential in our food producing regions as well as in urban areas.

Standards for effluent discharge set by local regulations in South East Asian countries are often not as high as those set by countries such as Europe and Japan. In other words; water resources are not equally regarded as precious and worthy of protection. Until the time when it is possible to bring standards to the same level, the implementation of environmentally responsible sewage treatments must be industry driven rather than government driven. This process can be helped by new products being brought to market, by clients making an investment in sustainable projects and by architects finding innovative solutions and integrating them with buildings and infrastructure design.

[i] Time; Oct 4, 2010; Walsh, Bryan; Code Blue. One woman’s quest to save our oceans the simplest way: protect them

[ii] Jeremy Hance. mongabay.com (September 29, 2010); Rivers Worldwide in peril: society treats symptoms, ignores causes

[iii] The Star; Dec 6th 2006. Gas subsidy for interior

More by Sarah Greenlees The Tower to the Memory of a Tree

Related Posts